Tire shredding is the method of reducing whole tires into smaller, uniform pieces that can be repurposed or recycled. Modern shredding systems are designed to handle high volumes of rubber, steel belts, textiles, and even embedded materials, turning waste (typically difficult to handle) into a resource-rich output.

Whether the end result is tire-derived fuel, rubber mulch, or crumb rubber, shredding is the first step in this sustainable process.

So, how does tire shredding actually work?

Let’s break it down.

The Tire Shredding Process

1. Initial Sorting & Inspection

Before shredding begins, tires are inspected for contaminants or foreign materials. Oversized truck or specialty tires may be pre-cut or processed separately to ensure safe handling.

2. Primary Shredding

Whole tires enter the primary shredder, which uses slow-speed, high-torque rotary cutters to tear the tire into large chunks, typically 4 to 6 inches in size. These machines are built to handle steel-reinforced sidewalls and aggressive tread designs.

3. Secondary Shredding (As Needed)

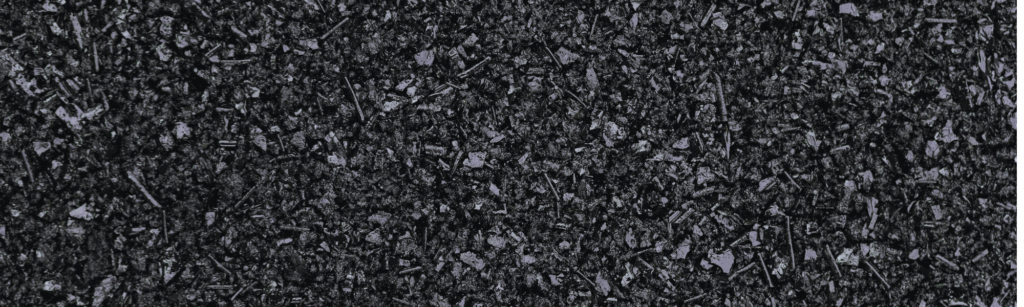

If finer material is required, the chunks move to a secondary shredder for further size reduction. This produces smaller, more consistent pieces, ideal for applications like playground mulch, road surfacing, or rubberized asphalt.

4. Separation of Steel and Fiber

Tires contain steel belts and textile fibers, which can be difficult process. Powerful separators extract steel from the shredded rubber, while air classifiers or vibrating screens remove lighter textile material. These materials can then be recycled separately, adding to the overall sustainability of the process.

5. Final Processing (Crumb Rubber, TDF, Mulch)

Depending on market demand, shredded rubber can be:

- Ground into crumb rubber for use in athletic turf, flooring, or molded products.

- Converted to Tire-Derived Fuel (TDF) for industrial kilns and power plants.

- Used as rubber mulch for landscaping and erosion control.

Tire shredding may seem like a behind-the-scenes process, but it’s actually a frontline solution in the global shift toward tire sustainability. As demand rises for recycled materials and cleaner fuel sources, the ability to process tires efficiently becomes more valuable than ever before.

At Traxion Materials, we utilize industrial-grade shredding technology as an integral part of our Tire LifeCycle Network.

Our advanced shredding machinery and integrated logistics network allow us to scale responsibly, proudly serving municipalities, fleets, tire retailers, and sustainability-driven corporations across the region.

Learn more about our shredding operations and sustainability solutions at www.traxionmaterials.com.